Lacto Japan Group, as a company engaged in food business, places strong emphasis on the procurement and supply of safe and reliable products. We ensure thorough safety verification not only of the suppliers with whom we work directly, but also by tracing back to producers such as dairy farmers.

As the department overseeing Lacto Japan’s quality management, we have established the Quality Assessment Department. In addition to monitoring and responding to laws and regulations related to quality and collecting relevant information, the department works closely with other divisions to verify that imported foods comply with Japanese laws and to confirm that they are safe for consumption. The department also manages quality-related information for each product and promotes the digitalization of such information to further enhance product safety.

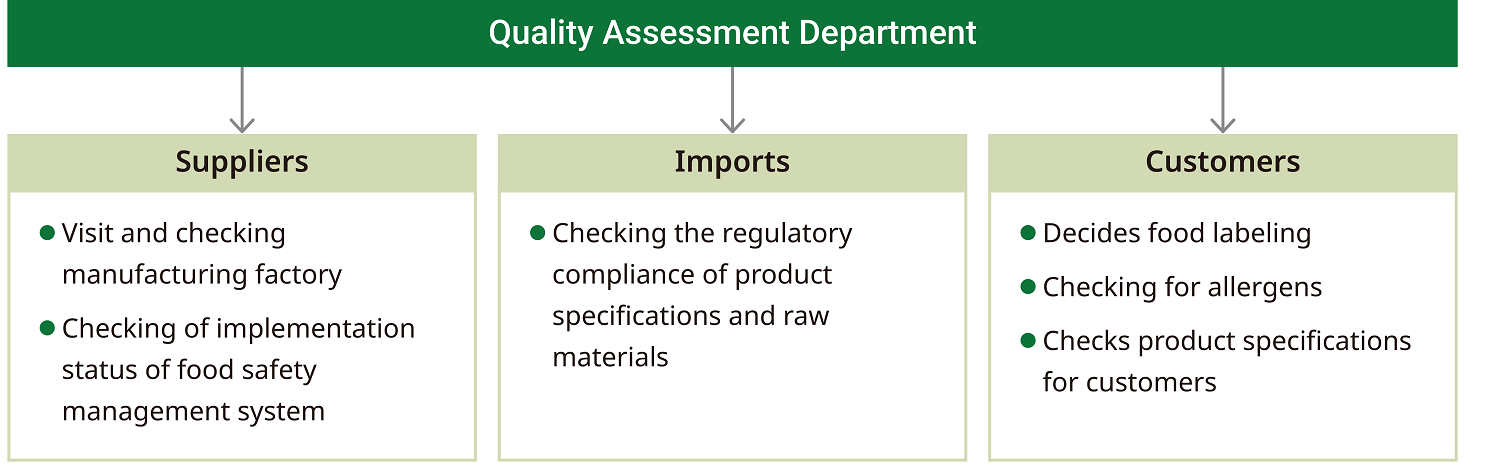

The Quality Assessment Department works to ensure that safe and reliable products are delivered at every stage of procurement, import, and sales.

For a trading company like ours specializing in food products, verifying suppliers is the first step in ensuring product safety. Employees of Lacto Japan Group visit suppliers around the world in person to confirm the safety of the products.

In the import process, we trace products back to their original raw materials to verify that they meet Japanese standards.

For domestic sales, we determine food labels in accordance with the Food Labeling Act. We also check allergenic substances, which may be subject to differing labeling requirements across countries, to ensure that safe and reliable products are delivered to customers.Product specification sheets are submitted to only after being reviewed by the Quality Assessment Department.

Lacto Japan Group works to prevent quality issues before they occur by reviewing manufacturing processes based on the knowledge and expertise cultivated through many years of experience. When necessary, we request improvements from suppliers to ensure the delivery of safe and reliable products.

We are conducting thorough quality and safety management at the cheese manufacturing plants that we are operating in Asia, as well.

At Lacto Japan Group’s overseas production sites, Quality Assurance (QA) and Quality Control (QC) functions play key roles in quality management.

In recent years, QA and QC personnel have been making reciprocal visits to production sites in different countries to enhance the sharing of critical quality information. As a result, new initiatives have emerged, including the sharing and practical application of more effective quality management methods.

We will continue to promote information exchange among our plants and work to further strengthen our quality management capabilities.

All overseas production sites have obtained FSSC 22000, a GFSI-recognized certification.

At our overseas plants where products are manufactured, we implement rigorous safety management measures to mitigate risks such as food defense. We maintain robust security that prevents unauthorized entry through strict access control records, the use of fingerprint and retinal authentication, and the installation of surveillance cameras.

When receiving raw materials, we ensure that loading and unloading take place strictly within designated areas, and only employees transport materials into the plant.

Manufactured products are managed meticulously by production lot number, enabling full traceability back to raw materials when necessary.