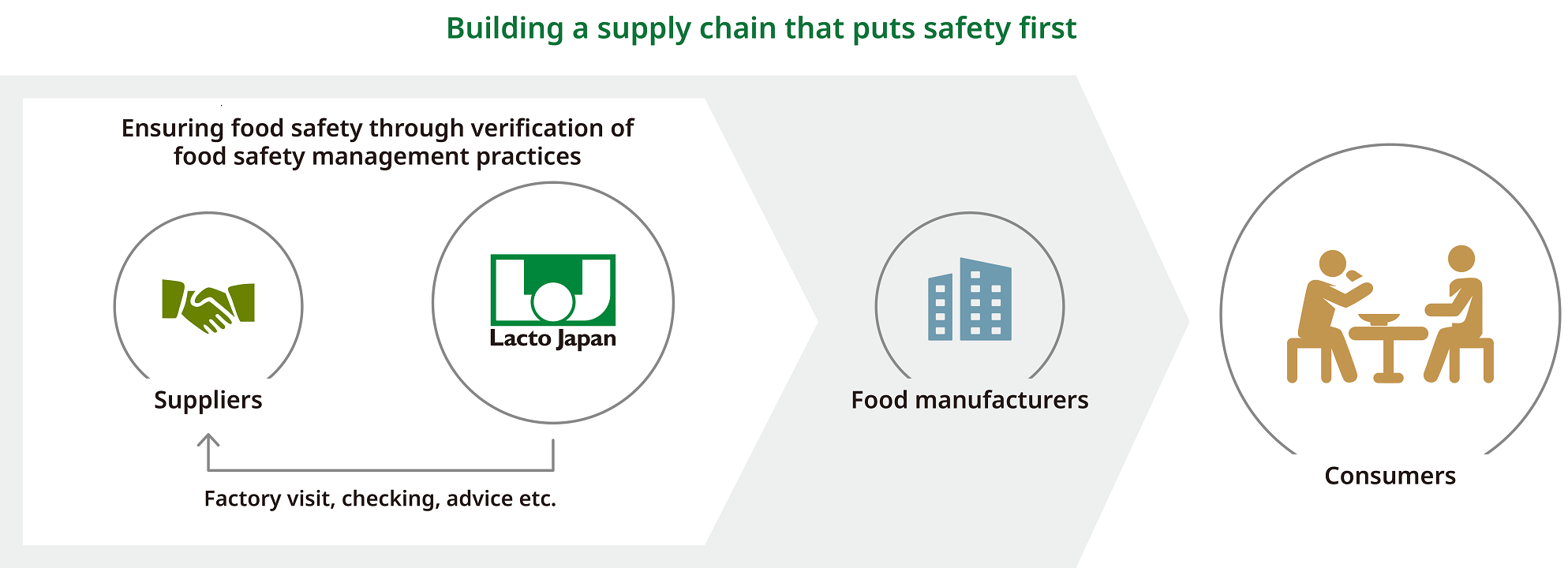

Lacto Japan Group considers verifying the safety of suppliers to be its top priority.

By visiting production sites directly, we confirm supplier quality, technical capabilities, responsiveness, and the presence or absence of risks in safety management throughout each manufacturing process. Through these on-site assessments, we ensure that we can consistently meet the standards required by customers. We also verify whether suppliers have established manufacturing processes that satisfy Japan’s import regulations and the safety and quality levels required by customers, as well as whether their facilities are equipped to address food defense and security requirements. If periodic supplier visits indicate that standards cannot be met and improvement is not possible, we, in principle, discontinue transactions.

In recent years, customers have increasingly conducted their own safety verifications and audits of suppliers, and staff at Lacto Japan always accompany them. During these visits, we identify customer requests and observations and, when necessary, ask suppliers to make improvements. Within the supply chain, our Group plays a bridging role between suppliers and customers to enhance product safety and quality.

To make appropriate proposals that address the increasingly sophisticated and diversified needs of customers , it is essential to build business models with a wide range of suppliers. By working closely with suppliers to ensure rigorous safety and quality management that aligns with regulatory frameworks in each country and with customer requirements, we foster strong partnerships that support mutual growth.

Lacto Japan Group handles a wide variety of dairy ingredients and cheeses made from raw milk, with more than 500 different products in total. Dairy ingredients require careful handling, and each country has its own import systems, which involve stringent inspections and procedures at the time of import. Our Group advances procurement based on the expertise we have cultivated through many years of trading in dairy ingredients.

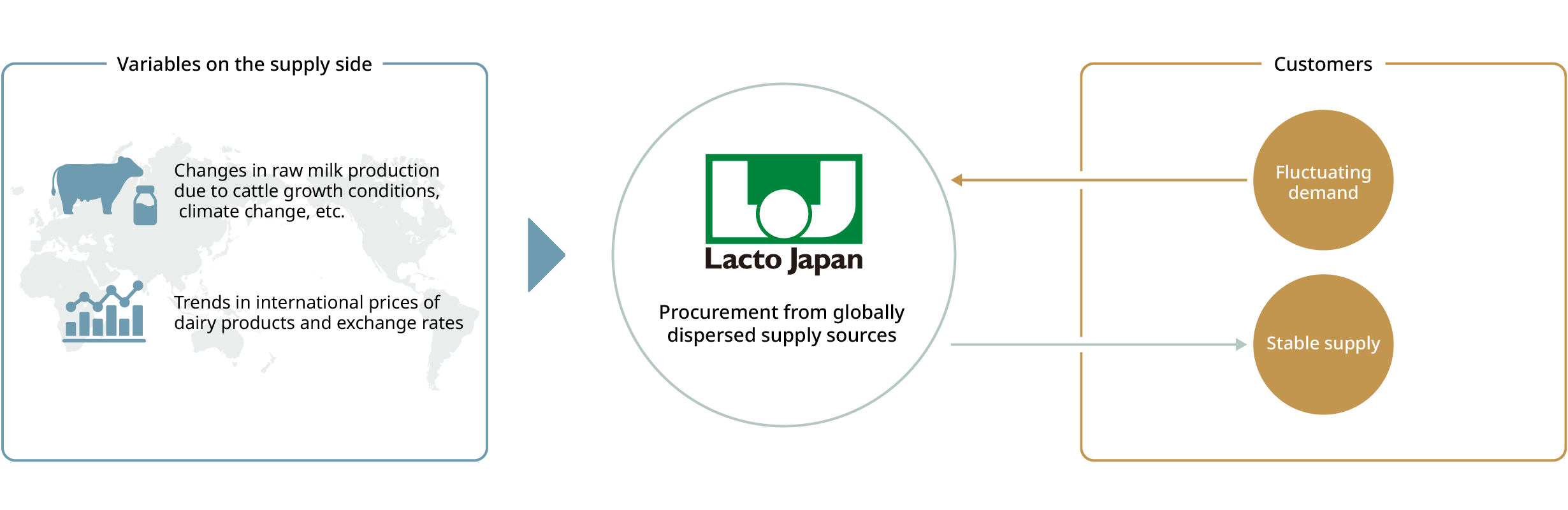

In Lacto Japan Group’s business model, an appropriate cattle-raising environment is essential for raw milk production. Because gestation, calving, and the seasons suitable for raising cattle each require a certain amount of time, production cannot be increased or decreased suddenly in response to short-term fluctuations in demand. In addition, climate change, drought, and the condition of feed crops affect cattle growth and raw milk production volumes. Imported products are also influenced by exchange rates and interest rate trends.

For these reasons, while carefully monitoring demand forecasts from customers, our Group works to secure supply sources across regions such as Europe, Oceania, and North America to ensure a stable supply.

Raw milk, the primary ingredient of dairy products, is generally collected from individual dairy farmers and transported to a factory, where samples are tested. After testing, the raw milk is stored in large tanks at the factory, where it is held under controlled conditions before being used in dairy product manufacturing. At that time, the factory inspects and records samples collected from each dairy farmer, enabling quality to be traced back to the producing farm and establishing traceability throughout the entire supply chain.

When beginning transactions with a supplier, we verify not only through documentation whether the supplier’s factory has implemented measures and equipment to prevent foreign matter contamination, as well as final shipment standards and employee safety measures, but also confirm these items on-site through direct visits.

In recent years, customers increasingly request information on product traceability and safety. To respond to this, we work to accumulate relevant information, and when customers conduct safety checks or audits at supplier factories, employees of Lacto Japan Group accompany them. In doing so, suppliers, customers, and our Group work together to understand the situation and implement improvements.

Lacto Japan’s Meat and Ingredients Division primarily imports and sells chilled and frozen pork and prepared pork products. In addition, we handle processed meat products such as prosciutto, salami, and pancetta, as well as chicken and processed chicken products.

Our sourcing centers on pork. Since the start of this business, we have traded with major packers in the United States, and we now procure pork not only from the U.S. but also from packers in Canada and Europe. From Europe, we also import spices, spice extracts, and rock salt in addition to prosciutto and salami.

Our U.S. suppliers, who have traded with companies around the world for many years, operate with strict standards for quality control throughout processing, traceability, food defense, and environmental considerations, making them highly reliable. Together with suppliers, we work to maintain strong quality control and stable procurement, and our employees regularly visit production sites to verify that production is being carried out in accordance with required standards.

For products supplied to customers in Japan, we often receive highly specific requirements regarding meat cuts, trimming methods, and packaging specifications. We provide guidance to suppliers on these advanced quality requirements and work closely with them to make improvements and ensure appropriate processing.